Hello everyone,

March, the month that heralds the end of 1Q each year has been a mixed bag of sorts thus far – leaning more to the positive side and ushering in a greater sense of optimism. Crude oil, iron ore, copper and precious metals appeared to be staging a comeback with prices heading northward – baffling many economists, in the process.

High five time?

Is it a mirage? Apparently not, except for crude oil where the sudden spurt (as we speak) seems to be riding more on sentiment rather than stark supply-demand stats. That the world is awash with oil cannot be wished away. Goldman Sachs‘ views on oil prices backed by logical reasoning, says it all.

Hope!

At the other end of the spectrum, the latest (March release) Markit-JP Morgan global manufacturing purchasing managers’ index (PMI) fell to 50 in February, hitting a fresh 39-month low in the process [Business Insider]. At the neutral level of 50, activity levels neither expanded nor contracted compared to a month earlier. Growth across developed markets reportedly slowed to a 33-month low. If global manufacturing is to avoid falling back into contraction, exports and international trade must witness an increase in the coming months.

Is this the bane of geopolitics? Which country is the last man standing in the oil price war? Any sane guesses?

The show must go on however…..

Endless possibilities

![]()

The initiatives taken by Boeing for recycling carbon fiber are well known. It is now supporting research at the Washington Storm Water Center on the potential use of recycled carbon fiber composites to strengthen permeable pavement – a porous paving material that can mitigate pollution from stormwater runoff. Permeable pavement is currently used on parking lots and side roads. However, it is considered too soft for use on more heavily-traveled streets and highways.The proposed research project will examine if the recycled carbon fiber composite can effectively strengthen the permeable pavement. Early test results are reportedly promising. It appears that water coming through the porous asphalt with carbon fiber is not toxic to aquatic life (as the chemicals are captured by the carbon fiber), whereas absence of the reinforcement allows toxic chemicals to permeate through the asphalt.

Blowing strong as ever

2015 was a watershed year for renewable energy in general and wind energy in particular. Records fell by the wayside. Per European Wind Energy Association (EWEA), 13GW of new wind capacity was added to the grid last year. Wind energy now provides a total of 142GW of capacity in Europe [Business Green]. The European wind industry accounted for 44% of all new power installations in 2015. Almost 50% of the new installed wind capacity in 2015 in Europe was in Germany (around 6GW). In the U.S., developers installed 16GW of clean energy in 2015. The American Wind Energy Association (AWEA) has released information that around 8.6GW of new wind capacity was added in 2015 [SeeNews Renewables]. This represents a whopping 73% jump in investments in new U.S. projects last year.

Turbine blade manufacturers were probably laughing all the way to the bank – such was the intensity in 2015. In the process, glass and carbon fiber manufacturers also benefited immensely.

“Move gas, not steel”

The use of composites, chiefly CFRP as a viable material of construction for CNG (compressed natural gas) cylinders/pressure vessels is in vogue. There is now a school of thought that CNG may be a more viable option for powering locomotives than LNG (liquefied natural gas) including capex and ongoing costs of compression versus liquefaction. Reportedly, CNG costs 30 to 50 cents less per DGE (diesel gallon equivalent) than LNG [HHP Insight]. Further it takes 2.4 times more energy to liquify natural gas than it does to compress it, according to studies that have been conducted. That CNG facilities are easier to maintain than LNG is an added advantage. Railroads stand to save around 74% more through use of CNG instead of diesel than they would using LNG. In spite of LNG’s energy density allowing for greater range, CNG is equally competitive through increase in range (over diesel locomotives) by 50% or even two-fold. The “move gas, not steel” slogan is gaining credence through companies detailing designs for LNG tenders using all-composite lightweight CNG fuel cylinders developed for over-the-road tube trailers. The tenders are scalable for capacities up to 10,000DGEs (Hexagon).

A revolution in the making ? You could say that!

Time is the essence

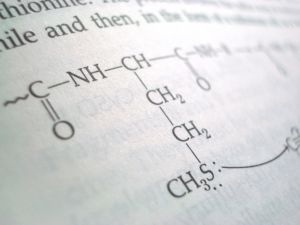

Curing of thermoset resins by cross-linking is well known. When cross-linked, thermoplastics are also turned into thermosets. Case in point is the cross-linking of polyethylene and polyamide in the pipe and automotive sectors respectively. The degree of cross-linking and curing is generally determined by wet chemical analysis – a method relying on chemical reactions between the material being analyzed and a reagent that is added (to the material). The main drawback to this method is the duration required – in excess of 8 hours before a quantitative result is obtained, not to mention the elaborate sample preparation involved [Plastics Today]. A German plastics research institute is exploring the use of single-sided nuclear magnetic resonance (NMR) that is significantly faster and also allows for inline process control. NMR is an advanced non-destructive testing (NDT) technique that generates info about the internal structure of a sample.The pros and cons of this NDT technique are being evaluated over a broad range of cross-linked and cured material systems.

Collaborate to succeed

Innovative polycarbonate composites reinforced with glass wool could be a commercial reality in the near future for automotive, information technology and electronics applications. Covestro and Tokyo-based Nanodax have recently signed an agreement on joint development work in this area. The Nanodax technology that allows glass wool as a reinforcing filler for plastics, features lower diameter fibers that are more flexible compared to conventional glass fibers [Chemicals-Technology]. Advantages in surface appearance and material processing aside, the optimized injection molding process is also expected to result in cost reduction for customers.

Yet another pathbreaking development is in the works that has success written all over, considering the fact that both companies are leaders in their respective fields.

Composites – the ultimate beneficiary

Battery-electric buses and CNG buses are rapidly gaining ascendancy globally-more so in the U.S. Both types of buses use composites to a great extent. In a new report published by the U.S. National Renewable Energy Laboratory (NREL), the battery-electric buses were found to be four times more fuel-efficient than comparable CNG buses. Results from on-road tests showed that the battery-electric buses demonstrated average efficiency of 2.15kWh/mile, which translates to about 17.48 per DGE. The CNG buses, in comparison, had an average fuel economy of just 4.51DGE [Busworld]. The battery-electric buses were also found to be more reliable than their CNG counterparts – logging 133,000 miles between road calls (MBRC), while the CNG buses had an MBRC of about 45,000.

Interesting and revealing stats for sure!

Market dynamics at play

The phenomenal success of fracking in the U.S. has resulted in an abundance of natural gas availability. The resulting impact on market dynamics of polyethylene (PE) and polypropylene (PP) has been discussed at length in several of my earlier blog posts way back in 2014. The use of lighter, less expensive feedstock (natural gas) in lieu of relatively more expensive naphtha is resulting in PE becoming more affordable and available and PP becoming scarcer and more expensive (as fewer pounds of propylene are produced from natural gas feeds). This is also reflected in recent price movements in PP [Plastics News]. Dehydrogenation of propane to make propylene is the main recourse to ensure availability of PP at reasonable price. In view of significant use of PP composites in the automotive sector, processors may have to brace themselves for market volatility.

Reinventing chemistry…to succeed

In the quest for reduction of cycle time to enable greater use of CFRP for automotive lightweighting, the onus has squarely been on resin producers, for starters, to develop fast curing resins. Parts production with autoclave quality in less than a minute is now possible by combining a new 30-second cure epoxy resin with the novel Dynamic Fluid Compression Molding (DFCM) technique. Huntsman claims that one-minute cycle times for structural components can be achieved without further post-curing with its new resin system that exhibits very fast demolding, enabling drastic reduction in cure time. The high elongation at break of the resin is a perfect fit for impact resistant composite part production [Plastics Engineering]. The circle is complete with the DFCM process yielding parts with reduced void content and fiber volume content of up to 65%. Other advantages are reduced equipment investment as it is a low pressure process, reduced waste and simple processing of heavy tow industrial fabrics.

The inroads being made by CFRP in automotive lightweighting owe a lot to several leading resin producers who have risen admirably to the challenge of modifying resin chemistry to result in fast curing resins.

As we approach the end of 1Q2016, there is a possibility that the International Monetary Fund (IMF) may further slash its January forecast of 3.4% global growth this year. Economic trends appear to be coming to full boil.

Are we in for an emotional roller coaster in the coming quarter? Fingers crossed on this.

Till the next post,

Cheers,

Twitter: @essjaycomposite

Website: www.essjaycomposites.com

You must be logged in to post a comment.